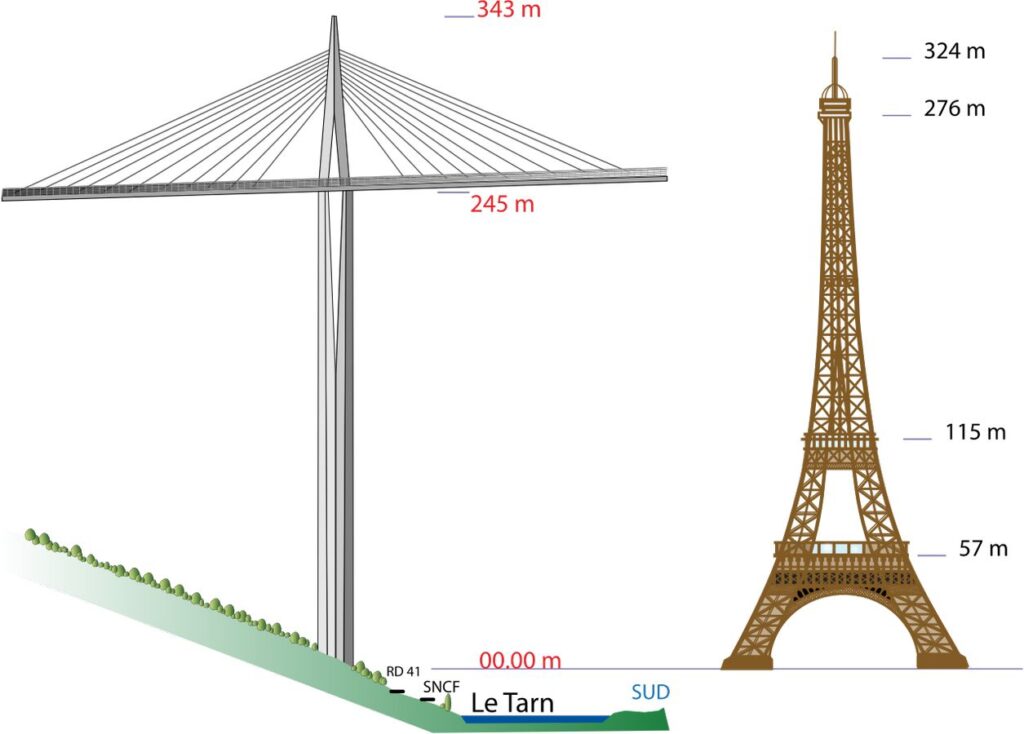

The Viaduct of Millau inaugurated on 14 December 2004

The Millau Viaduct is a multispan cable-stayed bridge completed in 2004 across the gorge valley of the Tarn near Millau in Southern France. The Millau Viaduct is part of the A75–A71 autoroute axis from Paris to Béziers and Montpellier. It was built in a record time of barely three years.

Author: Mike Lehmann, Mike Switzerland

The bridge has been consistently ranked as one of the greatest engineering achievements of modern times, and received the 2006 Outstanding Structure Award from the International Association for Bridge and Structural Engineering. The design team was led by engineer Michel Virlogeux and English architect Norman Foster.

The Compagnie Eiffage du Viaduc de Millau was successful in obtaining the tender. The superstructure is made entirely out of steel: the bridge with its orthotropic deck (width 28 m, height 4,20 m) and its 7 pylons (height 90 m) represent a total weight of 50.000 tons of steel.

Source: greisch.com

The steel road deck, and the hydraulic action of the road deck were designed by the engineering firm Bureau Greisch from Liège, Belgium. They carried out the general calculations and the resistance calculations for winds of up to 225 km per hour (140 mph). They also applied the launching technology.

The bridge road deck was constructed on plateaus at both ends of the viaduct, and pushed onto the pylons using bridge launching techniques. Each half of the assembled road deck was pushed lengthwise from the plateaus to the pylons, passing across one pylon to the next.

Photo: medium.com

During the launching, the road deck was also supported by eight temporary towers, which were removed near the end of construction. In addition to hydraulic jacks on each plateau pushing the road decks, each pylon was topped with a mechanism on top of each pylon that also pushed the deck. This mechanism consisted of a computer-controlled pair of wedges under the deck manipulated by hydraulics.

The mast pieces were driven over the new road deck lying down horizontally. The pieces were joined to form the complete mast, still lying horizontally. The mast was then tilted upwards, as one piece, at one time in a tricky operation. In this way, each mast was erected on top of the corresponding concrete pylon. The stays connecting the masts and the deck were then installed, and the bridge was tensioned overall, and weight tested. After this, the temporary pylons could be removed.

Creating several records, the Millau Viaduct is unquestionably an epitome of sophistication in civil engineering and construction and much more than just a bridge.

About the Author:

Bruno Dursin – Managing Director at Believe in Steel. Bruno has more than 30 years of experience in promoting steel & steel solutions. His clients benefit from his extensive network within the building industry.